Course Descriptions

MFGT-090 Measurements and Computations

3 units | 54 hours lecture

Focuses on measurements and calculations used in manufacturing related and technical career fields. Reviews basic computations and measurement systems used for shop and field applications.

MFGT-100 Industrial Safety

2 units | CSU 36 hours lecture

Provides instruction for safe work practice in an industrial environment. Emphasis on safety philosophies, terminology, fire safety, pressurized gasses and welding, chemical and electrical hazards, in addition to the safe handling, storage, and disposal of hazardous materials.

MFGT-101 Print Reading for the Machine Trades

2 units | CSU 36 hours lecture

Recommended Preparation: MFGT-090

Surveys the interpretation of technical drawings for machine trades. Explains print reading concepts and application, including use of sketches, multiview drawings, and line types. Covers print dimensioning from basic dimensioning through first angle projection, in addition to common assembly drawings and fasteners used in manufacturing.

MFGT-102 Geometric Dimensioning for the Machine Trades

2 units | CSU 36 hours lecture

Recommended Preparation: MFGT-101

Introduces the underlying concepts and practices of Geometric Dimensioning and Tolerancing. Focuses on dimensions and tolerances on engineering drawings per the ASME Y14 standard, datums, geometric rules, types, characteristics, and tolerance zones.

MFGT-103 Metrology for the Machine Trades

2 units | CSU 18 hours lecture, 54 hours lab

Prerequisite: MFGT-100

Explores the principles, techniques, and devices used within today’s dimensional metrology fields including industrial measurement and instruments such as gage blocks, steel rules, calipers, micrometers, depth micrometers, dial indicators, and height gauges. Covers equipment principles, measuring techniques, and best practices for the use of dimensional measuring equipment.

MFGT-104 Metallurgy for the Machine Trades

2 units | CSU 36 hours lecture

Recommended Preparation: MFGT-103

Surveys common metals and metal alloys used in today’s manufacturing industries. Covers physical and mechanical properties of ferrous and nonferrous metals for individuals working in the machine trades. Explores the basics of metal manufacturing, includes how metals and alloys are produced, and examines common testing methods used to measure and evaluate metal properties.

MFGT-105 Benchwork and Handtool Fundamentals

2 units | CSU 18 hours lecture, 54 hours lab

Prerequisite: MFGT-100

Introduces the theory and application of tools and electrically powered metalworking equipment. Emphasizes the safe use of common hand tools, bandsaws, drill presses, and grinding equipment. Prepares students for the National Institute for Metalworking Skills (NIMS) Machining Level I (Drill Press) certification exam.

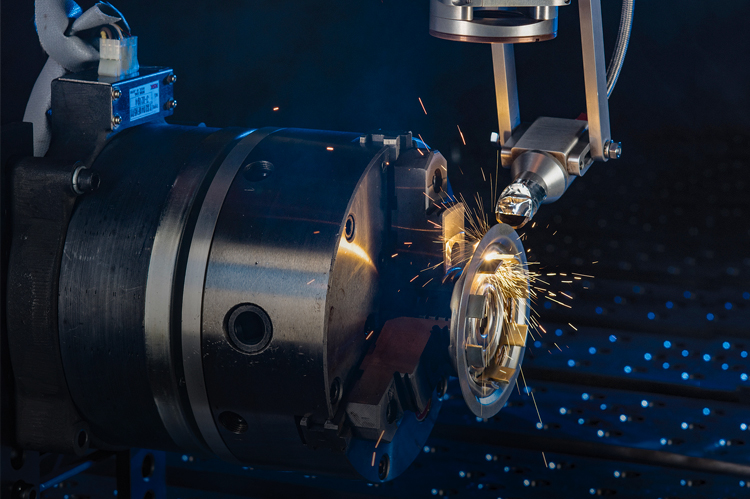

MFGT-106 Applied Manual Machining

4 units | CSU 36 hours lecture, 108 hours lab

Prerequisite: MFGT-100

Capstone course that examines theory and application of the safe use of manual lathe and milling machines. Focuses on building skills in turning and milling operations to produce accurately dimensioned parts and components. Prepares students for the National Institute for Metalworking Skills (NIMS) Machining Level I (Manual Milling and Turning Operations) certification exam.

MFGT 112 INTRODUCTION TO MANUFACTURING TECHNOLOGY

3 units | CSU 36 hours lecture, 54 hours lab

Introduces basic machine tool practices as they relate to common manufacturing operations, including measuring, cutting, and drilling common metals to standard drawings and specifications. Emphasis is placed on the care and safe use of related hand tools and machine shop equipment.

MFGT 113 MACHINING FUNDAMENTALS

3 units | CSU 36 hours lecture, 54 hours lab

Introduces the theory and application training in the use of machine tools such as the lathes, milling machines, drill presses, power saws, and bench grinders. Machine tool terminology, theory, math, part layout, and bench work using common and precision measuring tools is covered. Emphasis is placed on shop safety, housekeeping, and preventative maintenance of equipment.

MFGT 121 CNC 1: OPERATION AND MANUAL PROGRAMMING

3 units | CSU 36 hours lecture, 54 hours lab

Recommended Preparation: MFGT-113

Introduces the basic concepts of Computer Numerically Controlled (CNC) machine tools. Emphasis on safety, measurement, drilling machines, lathes, milling and grinding machines focusing on practices and setups used in industry.

MFGT 122 CNC 2: CONCEPTS AND PROGRAMMING

3 units | CSU 36 hours lecture, 54 hours lab

Prerequisite: MFGT-121

Surveys advanced level operation of Computer Numerically Controlled (CNC) lathe and milling machines. Emphasis is placed on safety, metallurgy, job planning, advanced programming, and solid modeling used in industry.

MFGT 131 CAD/CAM I

3 units | CSU 36 hours lecture, 54 hours lab

Introduces computer-aided design and manufacturing using MASTERCAM as a CAD/CAM environment, emphasizing the writing and running of CNC lathe programs and machining metal parts. Includes a review of machining and CNC programming fundamentals, the MASTERCAM environment and process overview, basic two-dimensional geometry construction and modification, process and toolpath planning, and 2-axis toolpath generation and editing.

MFGT 132 CAD/CAM II

3 units | CSU 36 hours lecture, 54 hours lab

Prerequisite: MFGT-131

Provides intermediate level CAD/CAM training using MASTERCAM and SolidWorks. This course is intended primarily for manufacturing technology students and industrial practitioners who have some experience with MASTERCAM.

My Canyons

My Canyons  Canvas

Canvas