News & Media

Media Release | April 2015

AWS Welding Journal

Media Release | April 9, 2015

LaserStar Newsroom

College of the Canyons Chooses LaserStar for Laser Welding Curriculum

Laser welding is fast becoming one of the top industry technologies. Many colleges are starting Welding Technology programs that include Laser Welding as part of the program. Santa Clarita Community College, better known as the College of the Canyons, is one of the many colleges to offer this new technology as part of their curriculum.

In 2012, LaserStar Technologies was fortunate to work with Tim Baber, Head of the Welding Technology Department at The College of the Canyons in Santa Clarita, CA. The program began with the purchase of fifteen 1900 Series LaserStar Industrial nd:YAG laser welding workstations for use in their Welding Technology program. We have also been on hand since to help with the setup and training of these machines. This was just the beginning of the program. The College is currently expanding their curriculum to add new high wattage laser welders including LaserStars FiberStar brand fiber laser welding workstations. We look forward to promoting Laser Technology to the next generation of students and workers.

View article online at LaserStar.

In 2012, LaserStar Technologies was fortunate to work with Tim Baber, Head of the Welding Technology Department at The College of the Canyons in Santa Clarita, CA. The program began with the purchase of fifteen 1900 Series LaserStar Industrial nd:YAG laser welding workstations for use in their Welding Technology program. We have also been on hand since to help with the setup and training of these machines. This was just the beginning of the program. The College is currently expanding their curriculum to add new high wattage laser welders including LaserStars FiberStar brand fiber laser welding workstations. We look forward to promoting Laser Technology to the next generation of students and workers.

View article online at LaserStar.

Media Release | April 1, 2015

Metal Sculpting Class

COC students are in the process of creating a sculpture for our campus. With the help of instructor/artist Idelle Okman Tyzbir this surprise sculpture will be completed in June. Cougar News reporter Allyssa Dickert took a sneak peak at their progress.

College of the Canyons Prepares Welding Workforce

Incorporates new automated technology curriculum into degree/certification programsAt College of the Canyons in Santa Clarita, California, welding has been a cornerstone of the schools Career Technical Education (CTE) program for more than 30 years a symbol of the colleges commitment to fostering regional economic development on numerous levels.

A core mission of many community colleges, including those in California, is to provide career technical education, explains Kristin Houser, College of the Canyons division dean of CTE. These programs offer the training needed for sophisticated, high-paying jobs. Our welding technology program is a poster child for one that is done well and achieves this mission.

Led by department chair Tim Baber, the colleges welding technology program strives to provide a number of industries construction, aerospace, fabrication, piping, petrochemical, motorsports, repair and maintenance, ship building and heavy equipment with skilled welders trained in the latest welding techniques, on the newest equipment. View the complete article here.

News Release | February 5, 2015

TouchSensing Welding Department Upgrades Robotic Automation Program In an effort to maintain its cutting edge exposure to manufacturing technology, the College of the Canyons welding technology department has installed Laser Touch Sensing adaptive control systems on two of its robotic welding machines.According to Lincoln Service Technician Christopher Joseph, "touch sensing is the first line of defense against poor weld joint repeatability."

An upgrade from conventional touch sensing, the laser touch sensing process improves the overall speed, efficiency and quality of the robotic welding process.

"With conventional touch sensing, a series of physical touches is required to determine the part orientation before the robotics can confirm any misalignment," said Tim Baber, department chair of the colleges welding technology program.

"But this methodical process is eliminated with laser touch sensing," added Baber. Part position is confirmed within seconds rather than minutes, and that 45 seconds you could save is a huge deal in a manufacturing environment.

Funding for the new systems was secured through a recent National Science Foundation (NSF) Advanced Manufacturing Processing Technicians grant awarded to the college.

Following installation, laser touch sense technology and training will be incorporated into the program curriculum by the fall 2015 semester.

COC Welding Technology Department Installs New System

Because of the departments heavy focus on the immediate development of employable workers, training students with cutting edge technology is a winning proposition for Baber.

"This type of training provides a lot of value to the student, and it can eventually provide value to the company they find employment with," Baber added. "With so many employers looking to robotics for improvement in their bottom line, students displaying an ability to operate laser touch sensing increase their employability and wage-earning potential."

News Release | January 19, 2015

LaserWeld

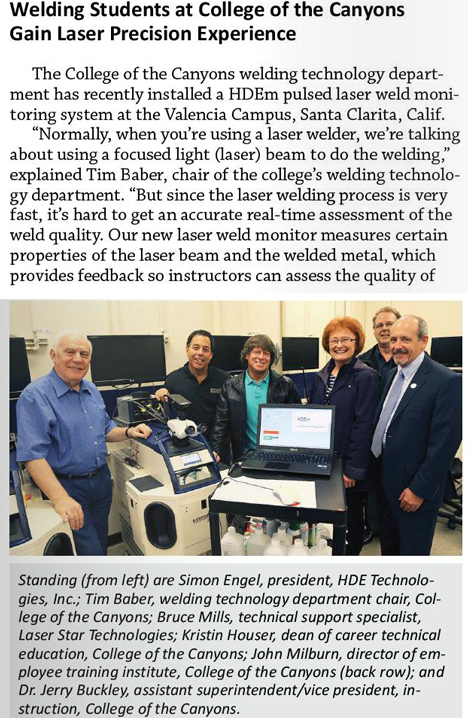

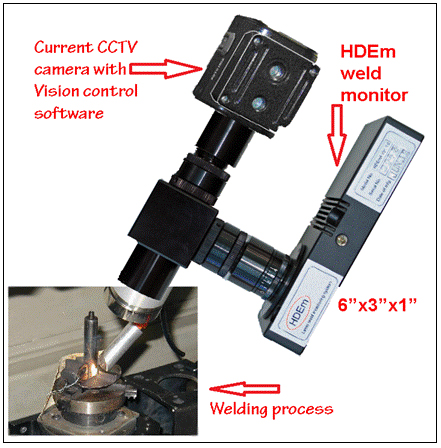

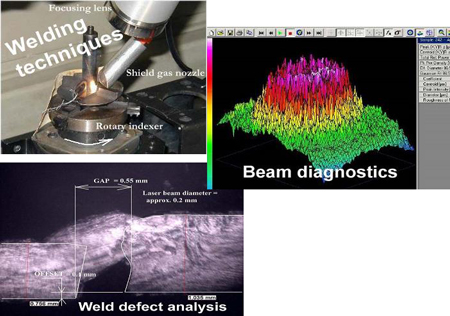

Welding Students Can Now Work with Laser Precision With the College of the Canyons welding technology departments recent installation of the HDEm Pulsed Laser Weld Monitoring System at the Valencia campus the first ever installed at an educational institution COC welding students are now able to learn the ins and outs of one of the industry's most innovative processes.Normally, when you're using a laser welder were talking about using a focused light (laser) beam to do the welding, said Tim Baber, chair of the colleges welding technology department. But since the laser welding process is very fast its hard to get an accurate real time assessment of the quality weld.

Our new laser weld monitor measures certain properties of the laser beam and the welded metal, which provides feedback so instructors can assess the quality of the weld and identify the location and the nature of weld defects, added Baber.

The HDEm system uses an external smart camera that is attached to the focusing head of the welding system which allows detection of gaps in the weld joint, mechanical interferences with the weld and the overall quality of welds produced by the laser.

Funding to purchase the HDEm device and develop the corresponding curriculum for student training was made possible through a recent National Science Foundation (NSF) grant awarded to the college to train students as advanced manufacturing and processing technicians and help meet current and future industry demand.

According to Baber, COC is the first learning institution of any kind to possess a laser weld monitor meaning many students at the college are training with technology that most 20-year industry veterans don't even have access to.

This technology was driven by the call of medical, automotive, aerospace and electronic industries to tackle the shortage of skilled labor, said Simon Engel, president of HDE Technologies and the inventor of the weld monitor.

The techniques industry currently uses to assess the quality of laser welds are expensive and provide limited data, Engel added. With the laser weld monitoring system, students will learn about laser welding and how to accurately assess and digitally report the quality of the welds within seconds after the welds are completed.

"Our ultimate goal is getting students as ready to go to work as possible, and to have more than just a conventional exposure to the industry." - Tim Baber

Baber and Engels relationship dates back to their time together working with the American Welding Society. Both are esteemed members of the Laser Welding Standards Subcommittee, of which Engel serves as vice chair. With the recent installation, COC welding students now have their hands on a phenomenal opportunity to get ahead in an industry primed for rapid growth.

Our ultimate goal is getting students as ready to go to work as possible, and to have more than just a conventional exposure to the industry, Baber said.

To learn more about the HDEm Pulsed Laser Weld Monitoring System please visit HDE Technologies, Inc.

My Canyons

My Canyons  Canvas

Canvas